Benefits of Investing in a Precision Cooling System for Small IT Applications

Network access and telecom rooms are housing more powerful and critical equipment as businesses rely on spaces to support an increasing number of critical applications. The technologies supporting the deployment of IP telephony, wireless networking, converged applications, and other equipment outside traditional IT data storage and management are finding their way into nontraditional, smaller spaces that weren’t designed as data centers.

These rooms also support important operational functions including time and attendance equipment, building maintenance alarms and security equipment. If a failure within a network access room occurs, organizations may face significant downtime, resulting in loss of service and revenue.

More powerful equipment generates more heat. When the equipment is trapped in a small, poorly ventilated space, heat can quickly raise the temperature to unsafe levels that reduce performance and shorten equipment life.

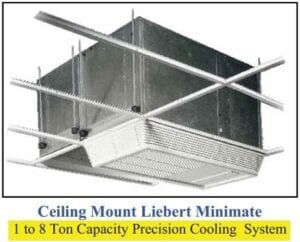

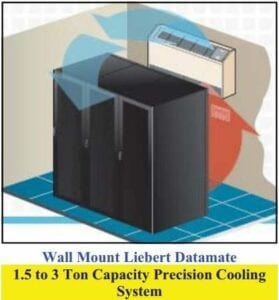

Developing an appropriate solution involves both overcoming the physical challenges imposed by the space and understanding the cost of downtime for the environment. The good news is that as your local Vertiv partner, we offer precision cooling solutions that allow powerful and sensitive network equipment to operate safely and reliably in almost any IT environment.

How to Select the Right Dedicated Cooling System

Cooling requirements depend primarily on the equipment type and room size. In cases where switch power requirements are very low, simple ventilation may suffice. Higher density equipment will typically require a dedicated cooling system. In fact, the Uptime Institute has reported that equipment located in the top one-third of a data center rack fails twice as often as equipment in the bottom two-thirds of the same rack. The organization estimates that for every increase of 18 degrees F above 70 degrees F, long-term electronics reliability falls by 50 percent.

When selecting a dedicated cooling system, it is important to consider what needs to cool, and how best to cool it. Not all cooling systems are the same. For example, there is a big difference between cooling electronics and cooling people. For starters, people add humidity to a room, and electronics do not. So, when selecting a cooling system for people, you have to consider the latent cooling capability of the cooling system, which is the ability to remove humidity, and the sensible cooling capability, which is the ability to remove heat.

When selecting a cooling system for electronics, you are strictly focused on its sensible cooling capability. Latent capability does not aide in the cooling process for electronics applications. Therefore, excessive investment in latent cooling capacity is a wasted investment for IT applications.

Comfort Cooling versus Precision Cooling Systems

Precision cooling systems have a sensible heat ratio of 0.90 to 1.0. This means 90 to 100 percent of their effort is devoted to sensible cooling and only a maximum of 10 percent is dedicated to removing humidity.

Therefore, it will take a larger comfort cooling unit to cool the same IT environment as a precision system. In general, it takes three tons of comfort cooling capacity to equal two tons of precision cooling capacity.

So, when these “value engineering” processes take place, most often a like-size cooling system exchange is made, (comfort system in place of precision system) although the sensible cooling performance is much different between the two. This results in the installation of a cooling system that does not have the cooling capacity to keep the IT equipment at the proper environmental conditions.

Comparison of Operating Costs

Comparing heat removal costs between comfort and precision cooling systems reveals significant operational savings for precision systems, even for relatively small data centers.

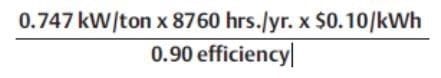

Here’s a basic calculation of operating cost comparisons between the two cooling approaches:

- Each ton of cooling requires 1.0 horsepower (or 0.747 kW)

- The compressor motors and fans are 90% efficient

- Electricity costs $0.10 per kilowatt-hour

- Humidification is required November through March (3,650 hours)

- The precision cooling system has a SHR of 0.90; the comfort system has a SHR of 0.60

First, calculate the cost per ton of cooling for a year:

This results in a cost of $727 ton/yr.

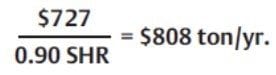

Then, determine the cost per sensible ton of cooling by dividing the total cost by the SHR for each system. For the precision cooling system, the cost per sensible ton is:

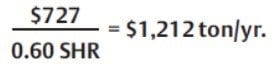

For the comfort cooling system, the cost per sensible ton is:

In this example, the operating cost to run a comfort cooling system for one year exceeds the cost to run a precision cooling system by $404 per ton of sensible load. This is consistent with the generally accepted principle that it takes three tons of comfort cooling capacity to equal two tons of precision capacity.

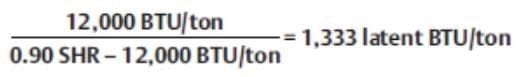

Another necessary comparison is the cost of humidification, which is determined by calculating the latent cooling that occurs per ton of sensible cooling.

For a precision system:

For a comfort system:

The comfort system expends 6,667 BTU of energy per ton of sensible cooling to remove humidity that must be replaced to maintain required data center moisture content of 45-50 percent.

The added cost is:

In this scenario, when considering all cooling and humidification costs, the operating cost of a comfort-based system exceeds the operating cost of a precision cooling system by $1,119 per ton of sensible cooling annually.

Precision cooling systems need less power to operate than comfort cooling systems and are more effective at removing sensible heat while controlling humidity levels. When initial costs and operating costs both are taken into account, precision cooling systems represent the most cost-effective solution to cooling critical IT equipment.

Precision Humidity Control

If humidity in a computer room gets too high, it may cause condensation in the electronics. If it gets too low, static electricity can fry components and alter data. And your magnetic media can suffer oxide shed, increasing the possibility of altered and lost data.

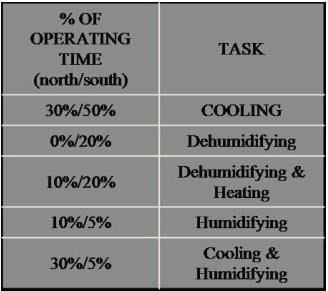

A relative humidity target of 45% ±5% is no problem for a Liebert precision air conditioning system. It has the accuracy and precision to meet that target, and it can operate in whatever mode is most appropriate (see chart, next section).

A comfort system has only two modes of operation…cooling and off. While it’s cooling, it’s also dehumidifying, but that’s incidental. Moreover, it is incapable of adding humidity during the winter season. When you get right down to it, a comfort system offers no control over relative humidity.

Operating Hours:

A precision air conditioning system is designed to operate whenever your electronic equipment is operating. For most companies, that means 24 hours per day, 365 days a year. The total is 8,760 hours per year. So, the circulating fan runs 8,760 hours a year, while the other components turn on and off as directed by strategically placed temperature and humidity sensors.

These percentages will vary depending on the room conditions, the heat load, and your geographical location. As your Vertiv partner, we will calculate the load represented by your room as a prerequisite to recommending a precision air conditioning system. From that calculation, we predict how the system will operate over a year’s time.

Not surprisingly, comfort systems are designed to operate whenever people are occupying the area. That usually turns out to be 8 hours a day and five days a week, but only during the cooling season, an average of 1,200 hours a year.

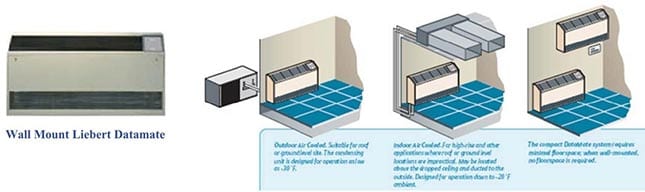

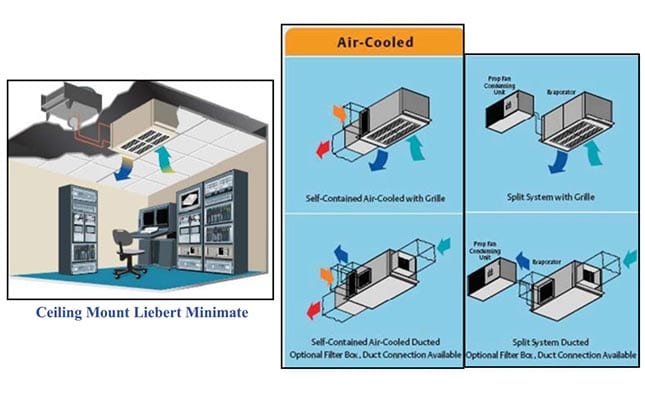

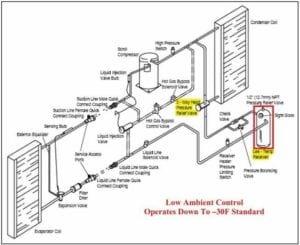

Low Ambient Operation:

The diagram below shows one method of low ambient operational control for Liebert small systems, involving a “Lee-Temp” receiver and a “3-way head pressure relief valve”.

During operation in cold ambient conditions, the system may encounter a low head pressure condition. When this happens, the 3way head pressure relief valve closes. The Lee Temp receiver, which is a refrigerant reservoir, then supplies refrigerant to the evaporator unit while the condenser coil fills with refrigerant.

As the condenser coil fills, less of the coil surface area is available for cooling of incoming refrigerant. Thus, the temperature will begin to climb, eventually restoring nominal system head pressure levels. When the proper head pressure is restored, the 3-way head pressure relief valve opens to allow normal system operation.

Service and Support:

Precision air systems often feature greater internal redundancy of components than comfort cooling systems, allowing them to continue operating in the event of some failures.

Your Precision Cooling Partner

As your IT infrastructure changes, the precision cooling system will have to evolve along with it.

To ensure optimal performance of the cooling system, our factory-trained technicians can assess, support, and service your environment and Vertiv’s Liebert precision cooling systems to enhance performance and reduce downtime.

If you’re interested in learning more about the benefits of a precision cooling system, contact us today.